Relatively recent advances in fabrication techniques have enabled the use of Iridium - an incredibly hard precious metal, for the construction of spark plug electrodes. Laser technology is used to weld the Iridium tip to spark plugs manufactured by both Denso and NGK. It's worth noting that spark plugs can't increase the potential power that an engine can generate but a more efficient spark will provide more efficient combustion and associated performance and economy benefits. A poor spark from a worn or low grade spark plug will reduce efficiency. An Iridium plug will produce a more efficient spark.

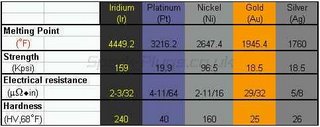

Notable properties of Iridium are its melting point - approximately 2450 degrees C, considerably higher than Platinum, and it's strength - approximately 8 times that of platinum. The table below compares the characteristics of Iridium with those of other precious/semi-precious metals commonly used in the construction of spark plugs.

NGK produce a product range known as Iridium IX and Denso produce Iridium Power spark plugs. Both are very high quality products using laser welding technology and manufacturing techniques perfected over a very long history of spark plug design and manufacture. Both manufacturers also manufacture OEM Iridium plugs, installed in some vehicles at the factory and usually having Iridium centre electrode and platinum chipped ground. Where an OEM Iridium plug is specified there is little to be gained by changing to an Iridium IX or Iridium Power plug. Champion have manufactured Iridium plugs for use in large industrial engines for quite some time but have not yet put any automotive parts into production.

Advantages of Iridium spark plug types

Due to the properties of Iridium, the spark plugs centre electrode can be made with a much smaller diameter than with platinum, Gold or gold palladium and copper/nickel types without sacrificing service life. The spark plugs potential difference is more concentrated at the tiny Iridium tip and hence less 'spark jump' voltage is required - this can be as much as 5,000 volts less than with standard plug types. Ignition is improved and less strain is placed on the ignition system. Benefits of improved ignition/combustion include better fuel economy, increased power/acceleration and especially better throttle response.

Construction of NGK and Denso plugs is similar for the most part, the big difference being Denso's use of a 0.4mm Iridium tipped centre electrode - claimed to be the world's smallest production centre electrode, where NGK's IX centre electrode is 0.6mm. As with NGK Iridium, and indeed most other spark plugs, the narrower the centre electrode is, the lower the potential difference (voltage) that is required to jump the gap between centre and ground electrodes. It follows that the Denso plug will require an even lower 'spark jump' voltage than the NGK plug. The Denso plug also utilises a 'u-grooved' ground electrode which is claimed to aid in the production of a 'flame core' which further improves the combustion process. In theory, all the benefits offered by NGK Iridium plugs are further improved by the Denso Iridium plugs - with the exception of service life. The smaller diameter of the Denso centre electrode means that less wear can take place before the plugs' optimum service life is exceeded.

Denso also manufacture long life Iridium power plugs such as SVK20RZ8, VK22PR-Z11 etc. These maintain the 0.4mm Iridium centre electrode but also have a platinum 'chip' in the ground electrode to allow performance to be maintained for a much longer service life (up to 60000 miles). These plug types are usually recommended for high power turbo charged engines where wear may otherwise be accelerated.

No comments:

Post a Comment